For any inquiries, questions or commendations, please call: +61 7 3813 7170 or fill out the following form

Vacuum Insulated Pipe

Your Premier Supplier for Vacuum Insulated Pipe

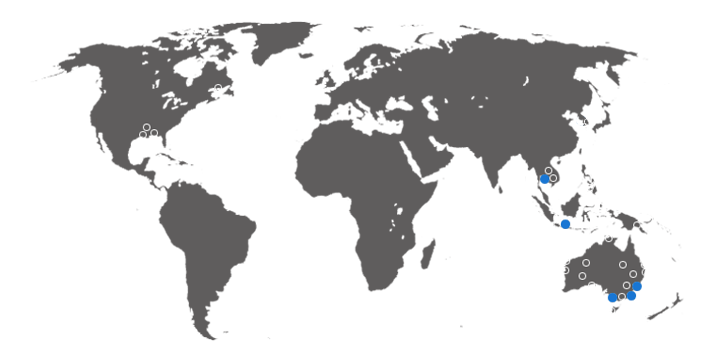

Cryeng Group is recognized globally as the leading supplier of vacuum insulated pipe (VIP), also known as vacuum jacketed pipe, pipe in pipe, and VJP. With extensive experience in executing large-scale, high-value projects, we pride ourselves on delivering high-quality products on time. Our expertise encompasses engineering design, thermal stress analysis, fabrication, site installation, and commissioning supervision.

Various Sizes and Configurations

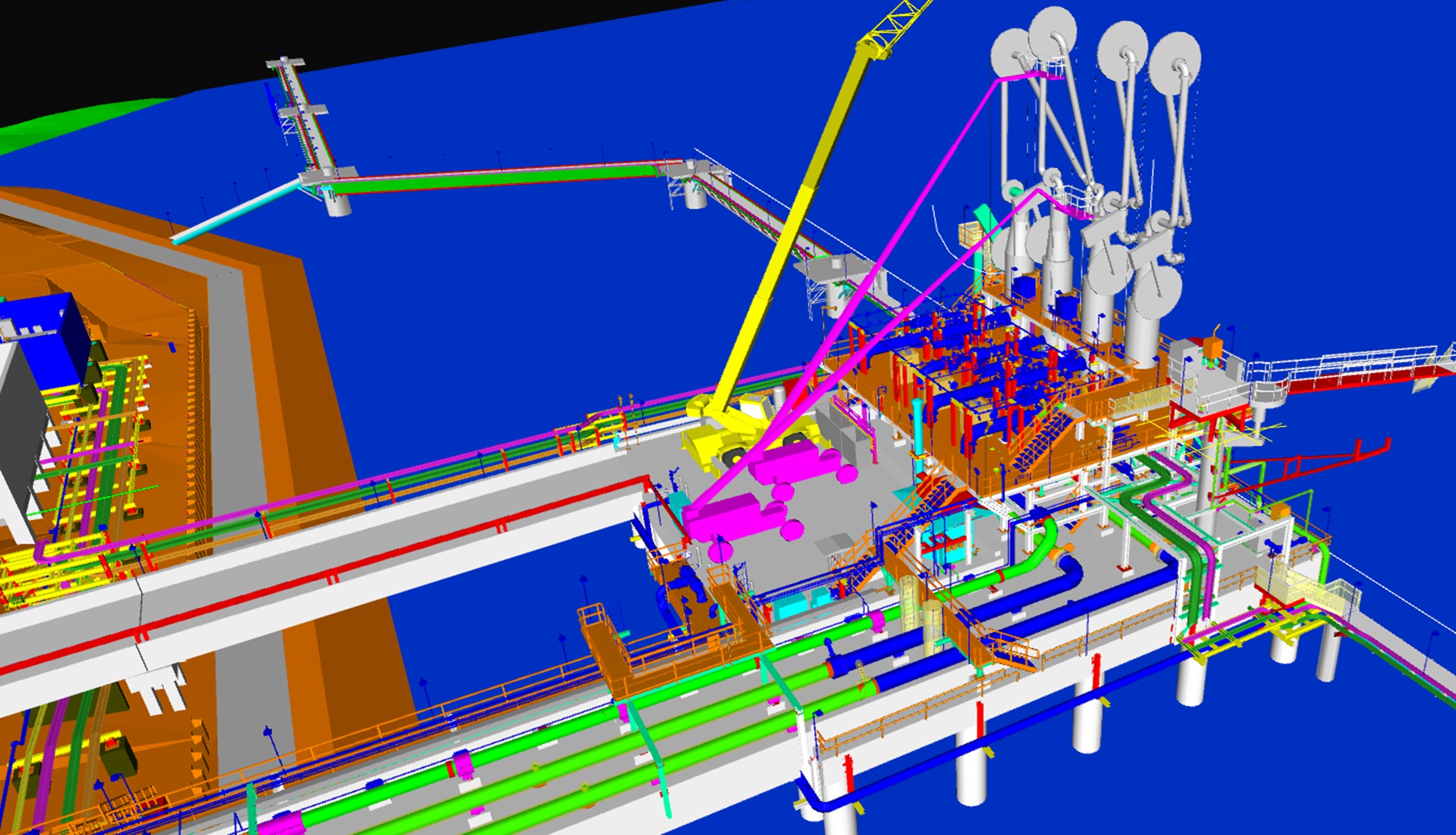

We specialize in fabricating vacuum insulated pipes in a wide range of sizes, from small bore lines (1″ NPS) to large bore lines (60″ NPS). All components, including fittings, branch connections, and field welds, are vacuum insulated to ensure minimal heat inleak throughout the system.

Superior Insulating Properties

Since their first use in LNG terminals, vacuum insulated pipes have been renowned for their exceptional thermal insulating capabilities. Cryeng Group designs its VIP to counteract the three methods of heat transfer: conduction, convection, and radiation. Compared to traditional mechanical insulation methods like foam, cellular glass, and PIR, our VIP offers up to 10 times better thermal insulation.

Maintenance-Free and Highly Durable

Cryeng’s VIP features a carbon or stainless steel jacket that extends the length of the pipeline, providing an airtight seal to the core pipe. This design maintains a high vacuum vapor barrier, ensuring maintenance-free operation for over 40 years. Unlike traditional insulation with a thin vapor barrier susceptible to weathering and requiring replacement every 5-10 years, our VIP offers long-lasting durability.

Eliminating Expansion Loops

Our engineers conduct comprehensive pipeline analyses using ABAQUS and CAESAR II analysis software. By strategically placing axial stops, expansion joints, and field welds, we localize and manage thermal movement, reducing or completely eliminating the need for expansion loops.

Double Containment for Enhanced Safety

In response to stringent regulations by government and independent bodies, double containment has become a primary consideration for LNG pipelines. Our VIP has been approved by the Federal Energy Regulatory Commission (FERC) for use in various states. Cryeng is recognized as a leader not only for superior insulation but also for providing robust secondary containment.

Efficient Site Installation

Each VIP spool leaving our factory is fully insulated and ready for installation, requiring only the insulation of field welds on-site. This significantly reduces site-based man hours compared to traditional foam insulation methods.