Leaders in Cryogenic Tank and Vessel Fabrication

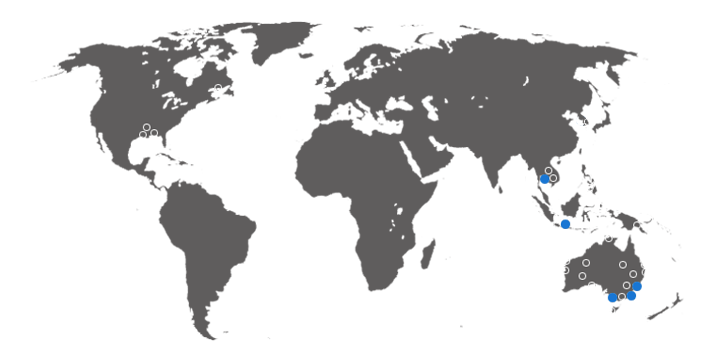

At Cryeng, we take pride in having designed and fabricated over 2,000 cryogenic tanks, vessels, surge drums, and pressure bullets for clients worldwide. Our extensive portfolio includes designs for both static and dynamic applications, vertical and horizontal configurations, and encompassing the full range of liquefied cryogenic gases, including LNG, helium, and hydrogen.

Superior Construction for Optimal Performance

Cryeng’s cryogenic tanks feature inner vessels typically constructed from high-quality stainless steel, while the outer vessels are fabricated from either carbon steel or stainless steel to ensure robust vacuum insulation. For applications requiring enhanced thermal insulation, such as helium and hydrogen storage, and scenarios demanding extended hold times, we offer nitrogen-cooled thermal shields in addition to vacuum insulation.

Compliance with International Standards

Our vacuum insulated cryogenic tanks are designed and manufactured to comply with AS 1210, ASME VIII Pressure Vessel code, and other relevant international standards. Our state-of-the-art fabrication facilities are ASME U, R, and NB stamp certified, and our products can also be PED or CE marked, ensuring the highest quality and safety standards.