Global Leaders in Cryogenic Engineering & Manufacturing

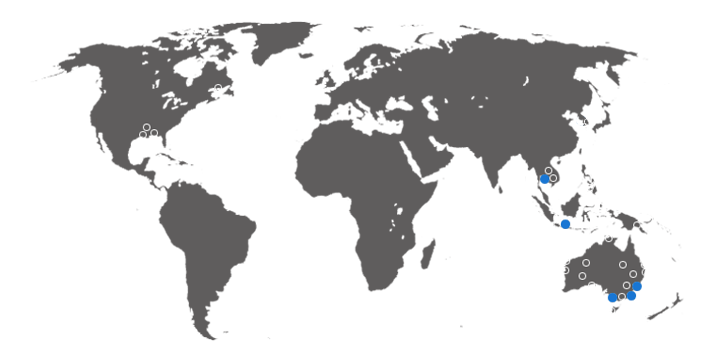

Cryeng Group are specialists in all stages of engineer-to-order cryogenic projects including concept, design, fabrication, client & project management services. We recognise that our success depends on our clients and our philosophy of innovation to deliver improved performance, reliability, and safety, has allowed us to design and build over 2000 cryogenic vessels to repeat customers worldwide. See our Capability Statement for further information.

7/241 Moo 6, Soi Pornprapha, Amata City Industrial Estate, Rayong 1140

J1.Raya Parung, Bogor Km.27, Situ Lebakwangi – Parung, Bogor 16330,

For any inquiries, questions or commendations, please call: +61 7 3813 7170 or fill out the following form